In the world of manufacturing, efficiency and reliability are key. Companies are always on the lookout for ways to enhance operations and tackle common hurdles. Enter the progressing cavity pump—a champion in transforming industrial processes. Known for their unique design and robust operation, these pumps are becoming the go-to solution for a multitude of manufacturing challenges. In this blog post, we will explore how progressing cavity pumps can tackle five common issues encountered in manufacturing applications. By the end, you’ll understand why these pumps are an essential asset for any manufacturing operation striving for excellence.

What Are Progressing Cavity Pumps?

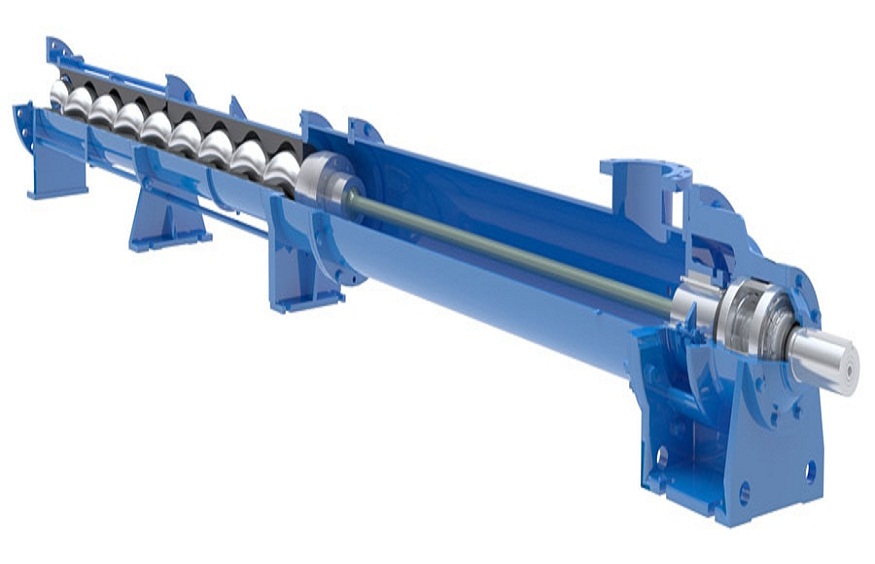

At the heart of any discussion about these pumps is their unique design and function. Progressing cavity pumps, often abbreviated as PC pumps, are positive displacement pumps known for their ability to handle viscous fluids, solids, and slurries with ease. They consist of a helical rotor that moves within a double-helical stator, creating cavities that progress from the suction to the discharge end.

This design allows them to move a wide variety of materials smoothly and continuously. Their ability to handle different viscosities and materials makes them ideal for industries like food and beverage, oil and gas, and wastewater treatment. Their versatility is one of their greatest strengths, making them indispensable in various manufacturing applications.

Handling Viscous Fluids with Ease

One of the most common challenges in manufacturing is handling viscous fluids. Whether it’s food products like peanut butter or industrial adhesives, moving thick substances can be a nightmare. This is where progressing cavity pumps shine. Unlike centrifugal pumps, PC pumps maintain a consistent flow rate regardless of fluid viscosity.

This capability ensures that even the thickest materials are transferred efficiently. In industries where consistent and reliable fluid handling is paramount, these pumps offer a solution that eliminates the need for additional processing equipment. By using PC pumps, manufacturers can reduce downtime and increase productivity, ultimately leading to cost savings.

Minimizing Wear and Tear

Manufacturers often face the problem of wear and tear on equipment due to abrasive materials. Traditional pumps can suffer significant damage over time, leading to costly repairs and downtime. Progressing cavity pumps are designed to handle abrasive fluids with minimal wear. The rotor-stator design ensures that the contact between the moving parts is gentle, reducing friction and wear.

This durability makes them an excellent choice for industries dealing with abrasive slurries or other harsh materials. By minimizing wear and tear, PC pumps extend the lifespan of the equipment and reduce maintenance costs, providing manufacturers with a reliable and cost-effective solution.

Achieving Steady, Pulsation-Free Flow

In many manufacturing processes, a steady and pulsation-free flow is crucial. Pulsations can lead to inconsistent product quality, damage to equipment, and increased energy consumption. Progressing cavity pumps excel in providing a uniform flow, free from pulsations. This smooth operation ensures that the manufacturing process runs seamlessly, maintaining product integrity and reducing the risk of equipment damage.

For industries where precise dosing and consistent output are essential, such as chemical manufacturing or pharmaceuticals, PC pumps offer a level of control that is unmatched by traditional pump systems. Their ability to deliver a smooth, continuous flow makes them a preferred choice for many manufacturers.

Efficiently Handling Solids and Slurries

Manufacturing applications often involve handling solids-laden fluids and slurries. These materials can clog traditional pumps, leading to operational disruptions. Progressing cavity pumps are specially designed to handle these challenges. Their robust construction allows them to move solids and slurries without clogging or losing efficiency.

This capability is particularly beneficial in industries such as wastewater treatment or mining, where dealing with solids is a daily occurrence. By using PC pumps, manufacturers can maintain efficient operations, reduce the risk of clogs, and ensure that their processes run smoothly.

Reducing Energy Consumption

In today’s environmentally conscious world, energy efficiency is a top priority for manufacturers. Traditional pumps can consume significant amounts of energy, increasing operational costs and environmental impact. Progressing cavity pumps are known for their energy-efficient operation. Their positive displacement design allows them to move fluids with minimal energy input.

By reducing energy consumption, PC pumps help manufacturers lower their carbon footprint and save on energy costs. This efficiency aligns with the growing trend of sustainable manufacturing, making them an attractive choice for companies looking to enhance their environmental credentials.

Enhancing Overall Operational Efficiency

Overall, the integration of progressing cavity pumps into manufacturing processes can lead to significant improvements in operational efficiency. By addressing common challenges such as handling viscous fluids, minimizing wear, achieving steady flow, and reducing energy consumption, these pumps provide a comprehensive solution that enhances productivity.

Manufacturers can benefit from reduced downtime, lower maintenance costs, and increased reliability—factors that contribute to a more streamlined and efficient operation. In an industry where every minute counts, the advantages of using PC pumps are clear and compelling.

Progressing cavity pumps have revolutionized the way manufacturers handle common challenges in their operations. Their ability to efficiently manage viscous fluids, solids, and abrasive materials while reducing energy consumption makes them an invaluable asset in any manufacturing setting. By investing in PC pumps, manufacturers can overcome operational hurdles, enhance productivity, and achieve greater efficiency in their processes. For those looking to take their manufacturing operations to the next level, exploring the capabilities of progressing cavity pumps is a step in the right direction. Consider integrating them into your systems and experience the tangible benefits they bring to the table.